Mistake Proofing

Overview

There are two main focuses of mistake proofing:

- Prevention: To prevent a human error from happening.

- Detection: To immediately identify when an error has occurred and enable containment at source.

This course is designed to provide participants with the theoretical and practical knowledge needed to implement mistake proofing in both design and manufacturing activities. The primary emphasis is upon the achievement of major improvements in overall manufacturing performance

Approach

We combine theory with a workshop in which participants utilize their new knowledge to develop mistake-proofing applications that are ready to be implemented upon leaving the workshop.

- Theory is immediately applied during the workshop as students brainstorm and create mistake-proofing ideas using workshop concepts.

- Ideas are critiqued and refined to create applications that are immediately applicable.

What You Will Learn

- Unit 1. Introduction

- Unit 2. What is Mistake-Proofing?

-

Unit 3. Why Bother?

-

Unit 4. Who Performs Mistake-Proofing? Where?

-

Unit 5. Inspection Systems

-

Unit 6. Mistake-Proofing Applications

-

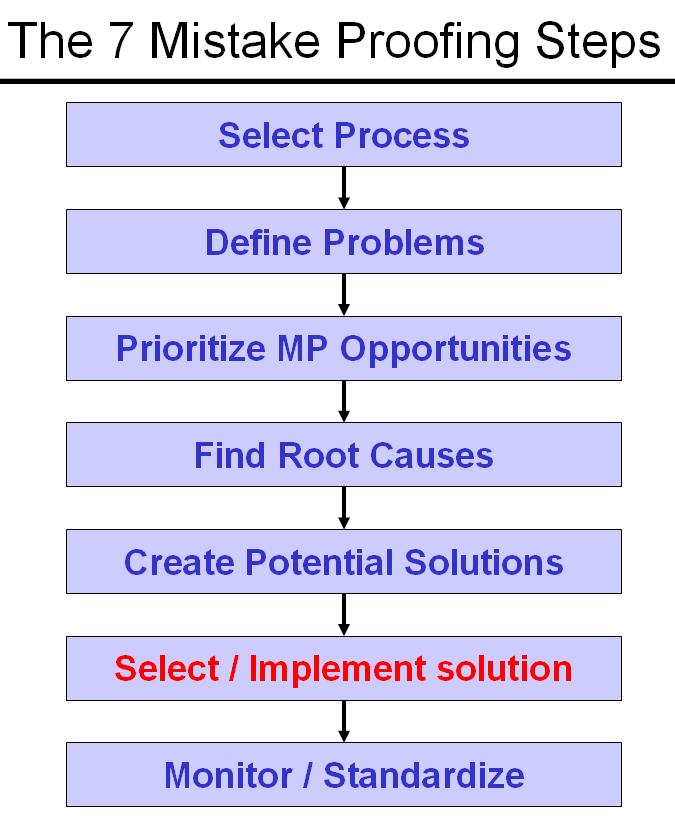

Unit 7. The Mistake Proofing Process

-

Unit 8. Group Mistake Proofing Exercise

-

Unit 9. MP Program Management & Sustainability

-

Unit 10. Action Plan / Wrap-up

Training Outcomes

Graduates will have the theoretical and practical knowledge needed to implement mistake proofing in design and manufacturing activities, and will thereby have the ability to make a significant contribution to improving their company’s manufacturing performance. During the course, participants will be required to brainstorm and develop mistake-proofing applications that are relevant to their own processes, and will be expected to have refined these ideas to the point that they will have at least one mistake-proofing application that is capable of being implemented within their own organization.

This course is primarily targeted at the technical, engineering, maintenance and production personnel who have the responsibility for achieving ultra-high performance levels.

WHAT PEOPLE ARE SAYING

SatiStar's Experience Makes The Difference!