Initial Stage Control

Overview

It’s tough to achieve superb order fulfillment performance if the overall product and process design, development and production launch processes do not deliver reliable cost, quality and delivery performance. Everyone knows even “small” design; development or launch (DDL) errors can cause major grief. These processes are knowledge and communication intensive and often involve multiple design databases, interdependent work processes, frequent changes, and long lead times. It is no surprise that the design, development and launch process is often an organization’s riskiest business process.

Initial Stage Control (ISC) is an integrated design and development planning and management control system designed to minimize these risks, deliver smooth launches and meet agreed-upon quality, cost and delivery performance targets.

Scope And Deliverables

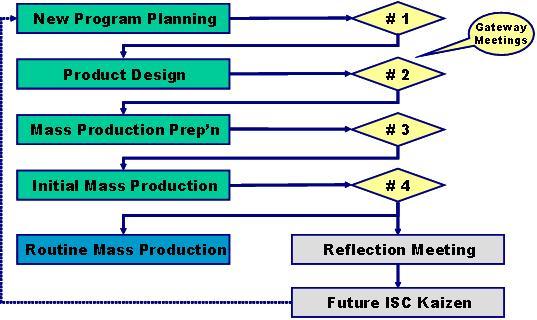

ISC begins on approval of the initial design and development contract with the customer. It continues through the processes of initial planning, product and process design, and pre-production preparation. It also includes the first 3 months of initial production, finishing with the formal hand-off of routine production responsibility to manufacturing.

A formal multifunctional DDL project team is created at the outset of the project. This team is fully responsible for planning, implementation and achievement of project deliverables and objectives at all phases of the project, and in particular for reporting at gateway meetings preplanned points in the overall DDL process.

At the outset, the project is classified into one of several standardized design and development streams depending on overall project risk. Each stream and its associated standardized project controls and reports are tailored to the project risk level.

These gateways are also used by management to review progress and plans on a portfolio of multiple projects very efficiently, and are their opportunity to understand and influence how the critical project concerns and issues are addressed.

The DDL team reports and closed loop control systems use report formats standardized across the organization and tailored to each of the five gateways. This provides excellent clarity and visibility on detailed DDL requirements and high organizational efficiency. Furthermore, based on the initial assessment of project risk, the project team will use one of several standardized reporting systems matched to the project risk level. Small, low cost projects with little risk will, for example, use a simplified DDL process as well as a simplified gateway and reporting system.

Unlike most hand-offs to production, responsibility in an ISC system is transferred to production only after three months of initial mass production has taken place. During initial mass production, the DDL team is responsible to track performance against objectives and to address gaps. Hand-off occurs at the final gateway meeting only after the DDL team has demonstrated that the new processes meet agreed-upon performance targets and the team has delivered agreed-upon system deliverables.

These deliverables include all the infrastructure, equipment, tools, processes, procedures, work instructions and training needed by manufacturing to run to production standards and targets.

Once the hand-off has occurred, manufacturing is now responsible for routine mass production.

ISC thinking also includes the use of a project reflection by the project team after hand-off. This drives a Kaizen (or Continuous Improvement) process that improves DDL processes and people capability.

The benefits of an ISC process tailored to your organization’s capabilities and needs include:

- Smooth launches that meet customer needs.

- Improved teamwork.

- Lower design and development costs.

- Lower ongoing production costs.

- Lower product cost.

- Improved product and process development cycle time.

- Lower design, development and launch risks.

- Increased profitability.

- Continuous improvement of the design, development and launch process.

- Continuous improvement of employees’ capability and know-how.

- A design, development and launch process that complements Lean Manufacturing thinking.

What We Will Do

- Map and analyze your organization’s current design, development, pre-production and launch processes

- Analyze your organization’s culture and business practice as they relate to the design development and launch processes.

- Facilitate the process by which your organization establishes and clearly articulates a vision of excellence for your overall design, development and launch processes.

- Facilitate the creation of conceptual and detailed Initial Stage Control processes tailored to your organization.

- Assure world-class design and development process designs and ideas are provided for consideration in the design of your new processes.

- Facilitate the creation of a clear roadmap and timeline.

- Facilitate the buy-in, deployment and successful implementation of the new processes.

- Propose an implementation methodology that shows immediate and highly tactical actions.

- Develop an agreed-upon approach for measuring and monitoring DDL progress using Key Performance Indicators tailored to your business needs.

- Create and support the deployment of appropriate project management and communications processes.

What We Need You To Do

- Provide the internal leadership needed to help support the project.

- Ensure the active participation of the leadership team in the improvement project.

- Provide us with access to the required internal personnel.

- Authorize those personnel to provide us with the required information in a timely fashion.

- Assign resources as needed, including the creation of an ISC project team.

- Review and provide feedback on the ISC process designs proposed by the ISC project team.

WHAT PEOPLE ARE SAYING

SatiStar's Experience Makes The Difference!