5S Program

Overview

Originating in Japan by Masaaki Imai, 5S is a disciplined & systematic methodology for creating a clean, safe, orderly, high performance work environment. It is one of the foundations of a Lean System and supports the principles of waste reduction. With SatiStar’s knowledge and guidance, your 5S team will learn and implement the principles of 5S and benefit from improved efficiencies, reduced costs of operation, improved safety and greater team work and pride.

Scope And Deliverables

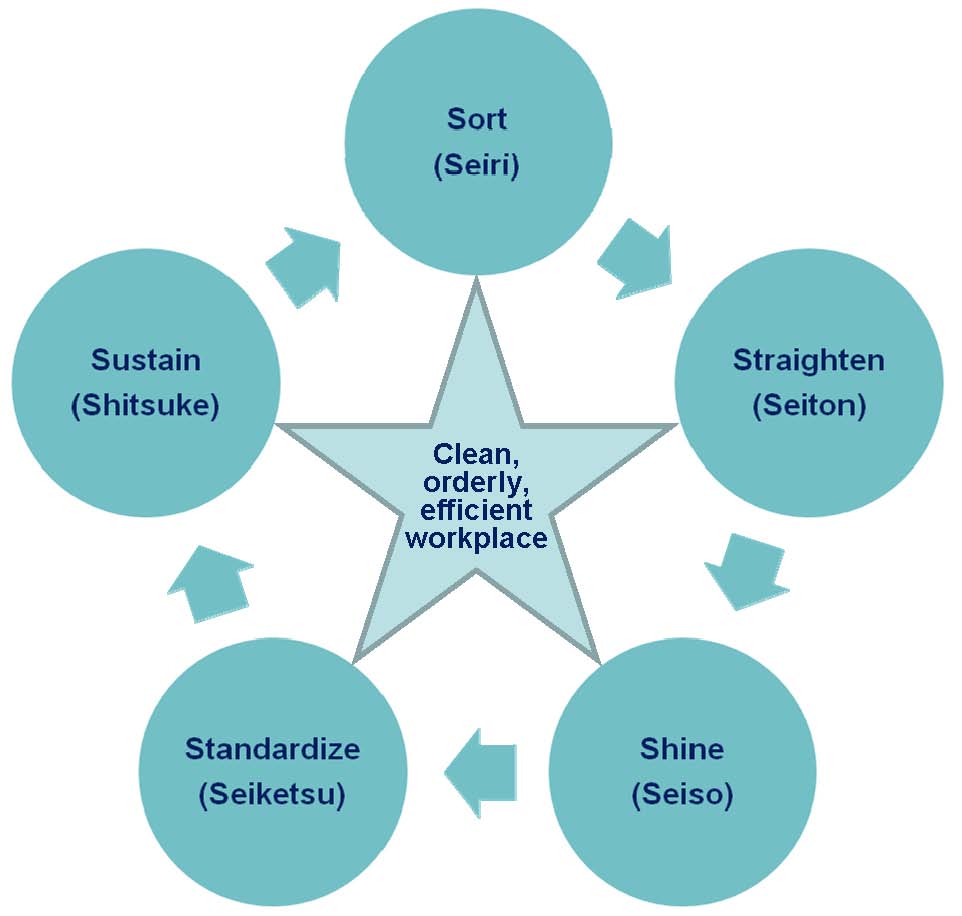

5S is an approach to productivity improvement that is equally applicable to all business processes including those in manufacturing, services and administration. 5S relies on the principles of sort, straighten, shine, standardize, and sustain to create a clean and organized work environment that will support the organization’s improvement goals.

5S is an approach to productivity improvement that is equally applicable to all business processes including those in manufacturing, services and administration. 5S relies on the principles of sort, straighten, shine, standardize, and sustain to create a clean and organized work environment that will support the organization’s improvement goals.

SatiStar’s experts will train, facilitate and guide your dedicated 5S team during your 5S project. Training is held in a workshop format and is designed to teach participants how to effectively implement the 5S methodology within their work areas. The course combines classroom theory and examples with practical experience applying the 5S methodology to their real-life work areas in the offices, labs, manufacturing areas, warehouses and showrooms. All of this is done under the guidance of our senior consultants.

After training is complete, SatiStar and your 5S team tackle the 5S implementation across the entire organization. In this 5S program, the 5S team will implement 5S projects and achieve measurable improvements in their work areas. Ownership of the 5S process is instilled in each employee – leading to strong commitment for its enduring success. SatiStar’s experts support this project with on-site consultants to ensure that the use of the tools is applied effectively, and to ensure that the gains are sustainable.

What We Will Do

- Train your team on the principles of 5S:

- Overview of 5S

- History

- Values and Principles

- Benefits

- Implementation Methodology

- Plan

- Sort, Straighten, Shine, Standardize, Sustain

- SatiStar’s 8 Step Implementation Approach

- The Kaizen-Blitz approach

- 5S Program Management

- Critical success factors

- Designing an effective 5S audit checklist

- Monitoring progress & Key Performance Indicators

- Radar Charts

- Recognition

- Overview of 5S

- Help in the selection of appropriate Lean team members.

- Facilitate your team through SatiStar’s 5S methodology.

- Guide the 5S team in evaluating and improving their work environment.

- Provide a management control system to ensure that the project delivers the desired results in a timely manner.

What We Need You To Do

- Commit to the 5S program.

- Assign required resources to the project.

- Ensure availability of required resources.

- Provide a suitable working area for the team’s activities.

- Authorize internal personnel to provide the 5S team with needed information and assistance.

- Ensure timely review and approval of the 5S team’s recommendations.

- Ensure timely delivery of desired results.

WHAT PEOPLE ARE SAYING

SatiStar's Experience Makes The Difference!